What is HMI? How HMI works with PLC?

Overview

HMI

stands for the Human-machine interface. It is a kind of device which interacts

operator with a machine or a computer to the industrial automation system.

An HMI stands for an interface; a wide term that can include MP3 players, mechanical PCs, family machines, and office hardware. Noteworthy, an HMI is substantially more explicit to assembling and procedure control frameworks. An HMI provides a visual portrayal of a control framework and provides ongoing information obtaining. An HMI can expand efficiency by having an incorporated control focus that is amazingly easy to understand.

A

Human Machine Interface (HMI) is actually what the name suggests; a graphical

interface that enables people and machines to communicate. Human-machine

interfaces differ broadly, from control boards for atomic force plants to the

screen on an iPhone. However, for this exchange, we are alluding to an HMI

control board for manufacturing-type forms. An HMI is brought together control

unit for manufacturing lines, outfitted with Data Recipes, occasion logging,

video feed, and occasion activating. So, one may get to the framework at any

minute for any reason.

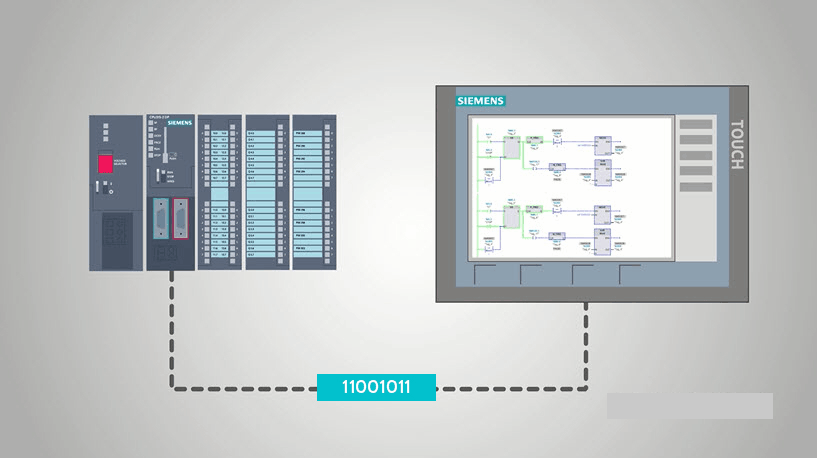

For

a manufacturing line to coordinate with an HMI, it should initially be working

with a PLC. It is the PLC that takes the data from the sensors and changes it

to Boolean polynomial math. So the HMI can disentangle and decide.

Types of HMI

Basically

there are three types of HMIs.

The Pushbutton

Replacer

The

pushbutton replacer HMI has streamlined assembling forms, incorporating every function of each catch into one location.

The Data Handler

The data handler is ideal for applications requiring consistent input from the

framework, or printouts of the production reports. With the data handler, you

should guarantee the HMI screen is large enough. Those are such things as

diagrams, visual portrayals, and production rundowns. The data handler

incorporates such things as diagrams, visual portrayals, and production

rundowns. The data handler incorporates such functions as plans, data

inclining, data logging, and caution taking care of/logging.

The Overseer

The last type of HMI refers to as the overseer. In the HMI systems, any application

can be involved with SCADA or MES. Because of this, the overseer is extremely

beneficial. It will be good if we run the Overseer HMI on the windows. It will

be also good if there are several Ethernet ports.

Evolution of HMI

If

we eagerly want to understand what the HMI device is, we need to just a step

back. We need to start from zero and also need to see how technology involved

with HMI.

First

of all, it all started with a button, and then there will come another function

which is light. After the light, there will come the switches. Then this all,

this hardwired device will visible, and it will be the electronic panels.

After

the inventions of HMI, within a few years, the world market of HMI has gone

through a huge evolution. There are remaining a lot of HMI experts in the

world. They do not have also doubt about that.

There is also arising one question that is what the things make the HMI systems potentially limitless? There are two answers on regards this question.

First

of all, it’s all about the software. In this modern-day, we are walking through

a standardization way, which before considered an optional thing. Also, the

company needs to compete with others for programs and SCADA systems.

In

the second, adjust with the new physical technologies.

Those

trends that mark basic utilize the technological device. Empowering individuals

that utilization them to locate a similar recognizable and simple use of cell

phoned and tablets.

HMI in the industrial Automation

At

last, we found a good pace intriguing part for the individuals who work in this

area. What is HMI’s connection with Industrial Automation?

Fundamentally,

an HMI gadget empowers the representation and control of utilizations. By

utilizing assets, such as I/O, SoftPlc, CoDeSys or Ethernet, and working

frameworks (far superior whenever installed), it enables you to speak with any

production system.

Contingent

upon the plant, the device’s highlights can change, regarding availability,

technology, and even measurements. Along these lines, in Industrial Automation

we can discover HMIs. That is fluctuating from standard 4.3 inches devices to

complex widescreen 15.6 inches shows. That is the reason anybody can locate the

correct solution.

So to simplify even more the operator’s activity, the touch screen technology

(capacitive or resistive) is accessible. That is permitting natural cooperation

with machines and production plants.

Presently

you recognize what is an HMI and what its job in Industrial Automation is.

Offer this article and maintain tailing us in control to constantly refresh

pretty much. That is all the most recent improvements in the human-machine

interface.

How HMI works with

PLC?

First

of all, consider different parts that are important to make an assembling

control framework work. The production line comprises of all the hardware that

plays out the work required in the production of the item. Next, consider the

different input/output sensors that screen temperature, speed, weight, weight

and feed rate. Third, choose the PLC that will get the information from the

input/output sensors. That also changes over the information into consistent

combinations.

Best Programming

Software of an HMI

When

we need to consider which programming software will use with HMI, there are

remaining three options for us to chose from Proprietary,

Hardware-Independent, and open software.

Proprietary

Software

Proprietary

software is the kind of software that is provided by the manufacturer. This

proprietary software is also typically easy to use. It also provides us with

quick development. The imperfection of the Proprietary software is that it is

only run on that specific hardware platform.

Hardware-Independent

Hardware-Independent

software is a kind of third party software that develops to program on several

different types of HMIs. The software gives much more freedom for the HMI

selection. The imperfection of this software is, it is not as user-friendly as

like as proprietary software.

Open Software

Open

software is a kind of software that fixes and selected by the advanced level

programmer. It also gives permits to the developer to have complete sincerity

in the design process.

Applications of HMI

The

HMI utilized all through different businesses including manufacturing plants,

candy machines, nourishment and refreshment, pharmaceuticals, and utilities.

HMIs alongside PLCs are ordinarily the foundation of the generation line in

these businesses. The incorporation of the HMI into manufacturing has

inconceivably improved tasks. The HMI considers supervisory control and

information procurement in the whole framework. The parameter changes are

attainable as the administrator's picking.